Storage:

- Outdoor Storage

- Indoor Storage

Outdoor Storage

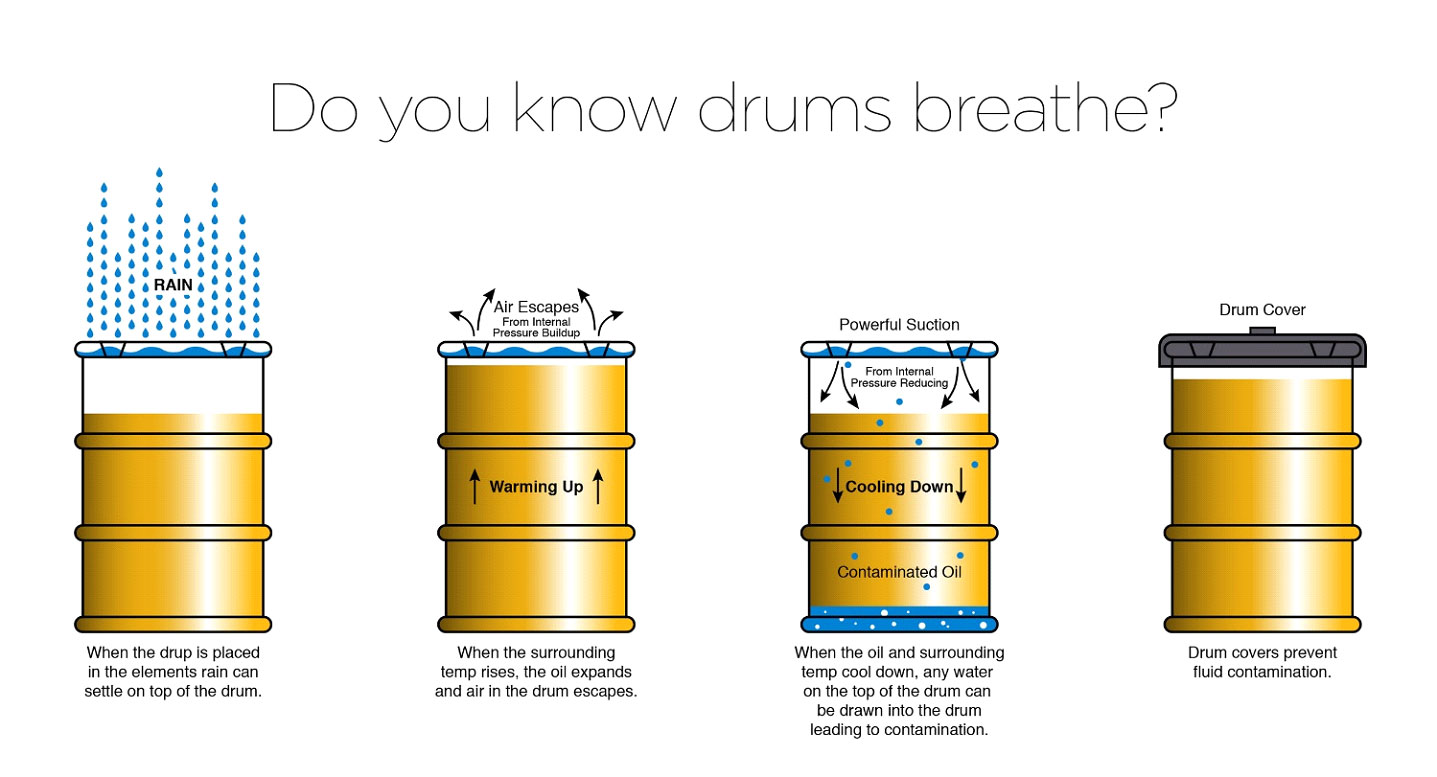

Ideally, lubricants should be stored under cover of a reasonably constant, moderate temperature. Weathering can obliterate the labels on containers, leading to possible mistakes in selecting lubricants for specific applications. Furthermore, widely varying outdoor temperatures,

consequent expansion and contraction of steams, may lead to leakage and wastage. The likelihood of contamination is also increased. Water can leak into even tightly closed drums by being sucked in past the bung as the drum and its contents expand and contract. Lube barrels standing in the open suffer variations in temperature and corresponding Variations in internal pressure. This leads to “breathing".

When containers must be stored outside or undercover, the following precautions are advised:

⦁ Lay drums on their sides. Position the drums so that the Door of drums are at 9 and 3 o’clock. This will ensure that they are covered by the drum contents. Thus minimizing moisture migration and drying out of the seals.

⦁ Prevent rusting of the undersides. In every case, barrels should be stored off the ground, well clear of surface water.

⦁ Drums at each end of a stack must be securely wedged to prevent movement.

⦁ Regular inspection should be carried out with a view to the detection of leaks and to make sure that Identification markings remain clear and legible.

Indoor Storage

Indoor storage is always preferable. The lubricants store should be kept dry at all times, to prevent the Corrosion of containers and storage should be located away from such possible sources of industrial contamination as coke dust, cement dust, and similar forms of grit.

Products with a flash point of 55°C or greater require no special fire precautions, but should be stored away from heat whenever possible. Oil-soaked sawdust, rags or cleaning paper must not be allowed to accumulate. If soaked with fatty oils they can ignite simply by, for example, coming into contact with a high temperature steam pipe.

Oil stores must be equipped with CO2, dry chemical or foam type extinguishers, and with sand filled fire buckets. Water should not be used for suppressing fires, as the burning lubricant may float on the surface and spread the fire. The lubricants store should be designated a 'No Smoking' area.

Handling:

The standard 208-liter barrel weighs about 185 kg when filled with oil. It is strong, being designed to be re-used several times, but is readily damaged by bad handling. The barrels must never be dropped when being unloaded or moved. The impact can burst the seams, causing subsequent leaking or contamination of the contents.There are many suitable methods of handling barrels, but the most widely accepted are:

• Forklift truck

• Two-wheel hand truck

• Triangular drum dolly

• Manual elevator

• Manual side-delivery stacker

• Chain hoist and trolley on 'I-Beam' bridge