The additive content in lubricating oils ranges from just a few parts per million to several percentage points depending on the function that the additives develop they may be classed as Improve the characteristics of the base oils (Viscosity index improver), Lubricant protective substances (antioxidants) or Substances giving new properties and protecting the metal surfaces of engines (detergents, dispersants, friction modifiers, anti-wear/Extreme Pressure (EP) additives, rust and corrosion inhibitors).

Very summarized lubricant additives can be classified as follows:

- Viscosity index improvers

- Pour point depressants

- Anti-foaming agents

- Lube Packages

- Detergents and Dispersants

- Anti-oxidants

- Many other kind of additives which use base on specific properties required.

Viscosity Index Improvers

Viscosity of oils sharply decreases at high temperatures. Low viscosity causes decrease of the oil lubrication ability.

Viscosity index improvers keep the viscosity at acceptable levels, which provide stable oil film even at increased temperatures. Viscosity improvers are widely used in multi-grade oils, viscosity of which is specified at both high and low temperature. Acrylate polymers are used as viscosity index improvers in lubricants.

POUR POINT DEPRESSANTS

Pour point is the lowest temperature, at which the oil may flow. Wax crystals formed in mineral oils at low temperatures reduce their fluidity.

Pour point depressant inhibits formation and agglomeration of wax particles keeping the lubricant fluid at low temperatures.

ANTI-FOAMING AGENTS

Agitation and aeration of a lubricating oil occurring at certain applications (Engine oils, Gear oils, Compressor oils) may result in formation of air bubbles in the oil - foaming. Foaming not only enhances oil oxidation but also decreases lubrication effect causing oil starvation.

Lube Packages

Lubricants packages giving new properties and protecting the metal surfaces of engines (detergents, dispersants, friction modifiers, anti-wear/Extreme Pressure (EP) additives, rust and corrosion inhibitors).

- Dispersants and Detergents

Dispersants keep the foreign particles present in a lubricant in a dispersed form. The foreign particles are sludge and varnish, dirt, products of oxidation, water etc.

Detergents neutralize strong acids present in the lubricant (for example sulfuric and nitric acid produced in internal combustion engines as a result of combustion process) and remove the neutralization products from the metal surface. Detergents also form a film on the part surface preventing high temperature deposition of sludge and varnish. Detergents are commonly added to Engine oils.

- Anti-Oxidants

Mineral oils react with oxygen of air forming organic acids. The oxidation reaction products cause increase of the oil viscosity, formation of sludge and varnish, corrosion of metallic parts and foaming. Anti-oxidants inhibit the oxidation process of oils. Most of lubricants contain anti-oxidants. The following materials are used as anti-oxidants:

- Zinc di-thio-phosphate (ZDP);

- Alkyl sulfides;

- Aromatic sulfides;

- Aromatic amines;

- Hindered phenols.

The Other Properties

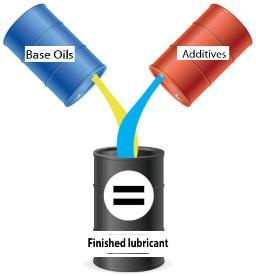

There are many types of chemical additives mixed into base oils to enhance the properties of the base oil, suppress some undesirable properties of the base oil, and possibly impart some new properties.

Many lubricant additives are available, and they are selected for use based on their ability to perform their intended function. They are also chosen for their ability to mix easily with the selected base oils, to be compatible with other additives in the formulation, and to be cost-effective.